Water treatment: An opportunity for today

Clean water flowing from a tap. And used water flowing down the drain. These two common functions–clean water in, dirty water out–are something many of us take for granted in our daily lives. But did you ever wonder what must happen to ensure the water coming out of your tap is indeed clean and safe? And what about the used water that goes down the drain? Did you know it is treated so it can be safely returned to an aquatic environment and reused once again?

“Water really is one of those great renewable resources—it’s something you can use time and again if it is properly treated to remove contaminants,” says John Brogly, Director of COSIA’s Water Environmental Priority Area.

“The fact is, we use water for all kinds of purposes including sanitation and personal hygiene, laundry and cleaning, and for manufacturing and industrial processes. And we continually clean it up so we can use it again and again.”

Many options to treat oil sands mine water

The oil sands industry also needs to clean up the water it uses. For decades now, oil sands process water has been stored in tailings facilities which also store the solid mineral material—sand, silt and clay— left over from oil sands processing.

Storage of water in these facilities is meant to be temporary, only for as long as it is needed to support operations. Continued water storage prevents the tailings facilities from being reclaimed back into natural landscapes. It also prevents reuse of the water for other purposes. These goals are driving industry’s proposal to treat water for safe release to the environment.

“Water chemistry and water treatment is a large and well-established area of study for scientists and the technical community,” says Brogly. “In fact, today’s water treatment systems are built on methods that go back thousands of years, such as applying heat to purify it, or sand and gravel filtration to reduce cloudiness caused by fine particles. Around 1500 BC, Egyptians discovered the principle of coagulation, a purification technique that causes solid particles in water to settle out. Technical insights and advances have continued ever since.”

Today, around the world, water and wastewater treatment technologies are very well understood. Many of them can be used to remediate oil sands process water. They comprise nine key treatment categories that can be combined as needed to meet desired treatment outcomes. The specifications for treating wastewater for release to the environment, for example, are different than those for treating water drawn from the environment for safe consumption by humans.

For its part, the oil sands industry has for decades invested significantly in testing and adapting the effectiveness of these treatment processes; it also sponsors related research that has been ongoing at several Canadian universities for more than three decades. These efforts have led to the development of new technologies for oil sands mine water treatment, including those that target treatment of organic compounds known as naphthenic acids.

They include a filtration/adsorption process that uses petroleum coke, a by-product of operations, to filter process-affected water in the same way a home water filter using activated carbon absorbs chemicals present in drinking water. It effectively removes suspended solids and dissolved organic constituents, making the water safe for release.

Another is a sunlight-activated treatment called Solar Pass™. It treats potentially harmful organic compounds in water using advanced oxidation technology, and was developed by H2NanO, a start-up company from the University of Waterloo.

Several treatments based partly on the remediating effects of time and natural processes are also being tested by COSIA members. These include full-scale and pilot-scale demonstrations of pit lake technology, as well as water treatment wetlands. They use various combinations of sedimentation, coagulation, flocculation and biological treatment technology, plus advanced oxidation if needed.

Brogly says a multi-pronged approach to water management is required, and industry continues to assess the full range of options and weigh their environmental trade-offs including generation of waste streams, higher energy use, and increased emissions.

Regulations expected in coming years

Water to be released will need to meet specific water chemistry criteria or treatment outcomes. These will be established in pending government regulations, expected in 2025. Once they are known, oil sands operators will make technology assessments and selections based on the needs of their individual sites and the characteristics of their water.

Sites may require multiple, different treatment technologies to achieve outcomes for different types of water and/or water uses. Brogly says operators are currently focusing on optimizing treatment technologies so they can meet release criteria once it is established.

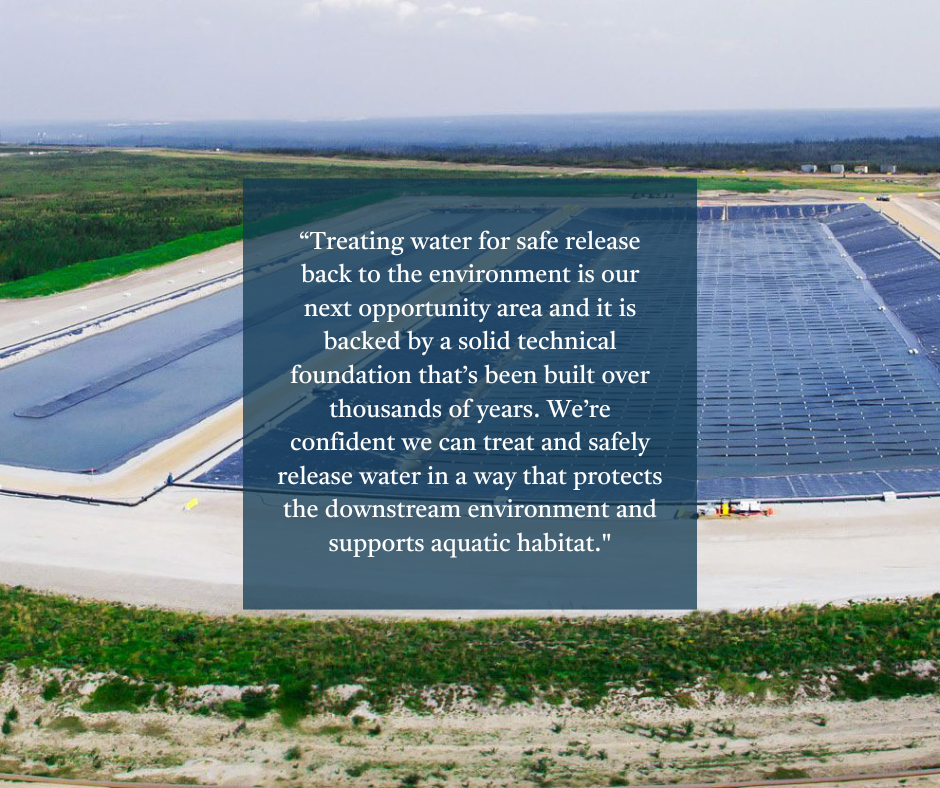

“The oil sands industry has an extensive record of innovating to meet its technical and environmental challenges,” says Brogly. “Treating water for safe release back to the environment is our next opportunity area and it is backed by a solid technical foundation that’s been built over thousands of years. We’re confident we can treat and safely release water in a way that protects the downstream environment and supports aquatic habitat. Those two goals are driving our technical decisions.”

——————————————————–

Interested in other stories on water management in the oil sands?

Check out these blogs:

- Mine water release 101: Everything you need to know: https://cosia.ca/blog/mine-water-release-101-everything-you-need-know

- Transforming tailings water with coke: https://cosia.ca/blog/transforming-tailings-water-coke

- How is oil used in Canada?: https://cosia.ca/blog/how-oil-used-canada